In industrial automation, robotics, and precision instruments, connector performance is often the “invisible bottleneck” that limits system reliability. Traditional connectors can be hard to route in tight spaces, difficult to service, and prone to interference. WAIN’s MI Series miniature high‑density connectors give engineers a space‑saving, easily maintained, high‑reliability alternative.

Break the Space Barrier

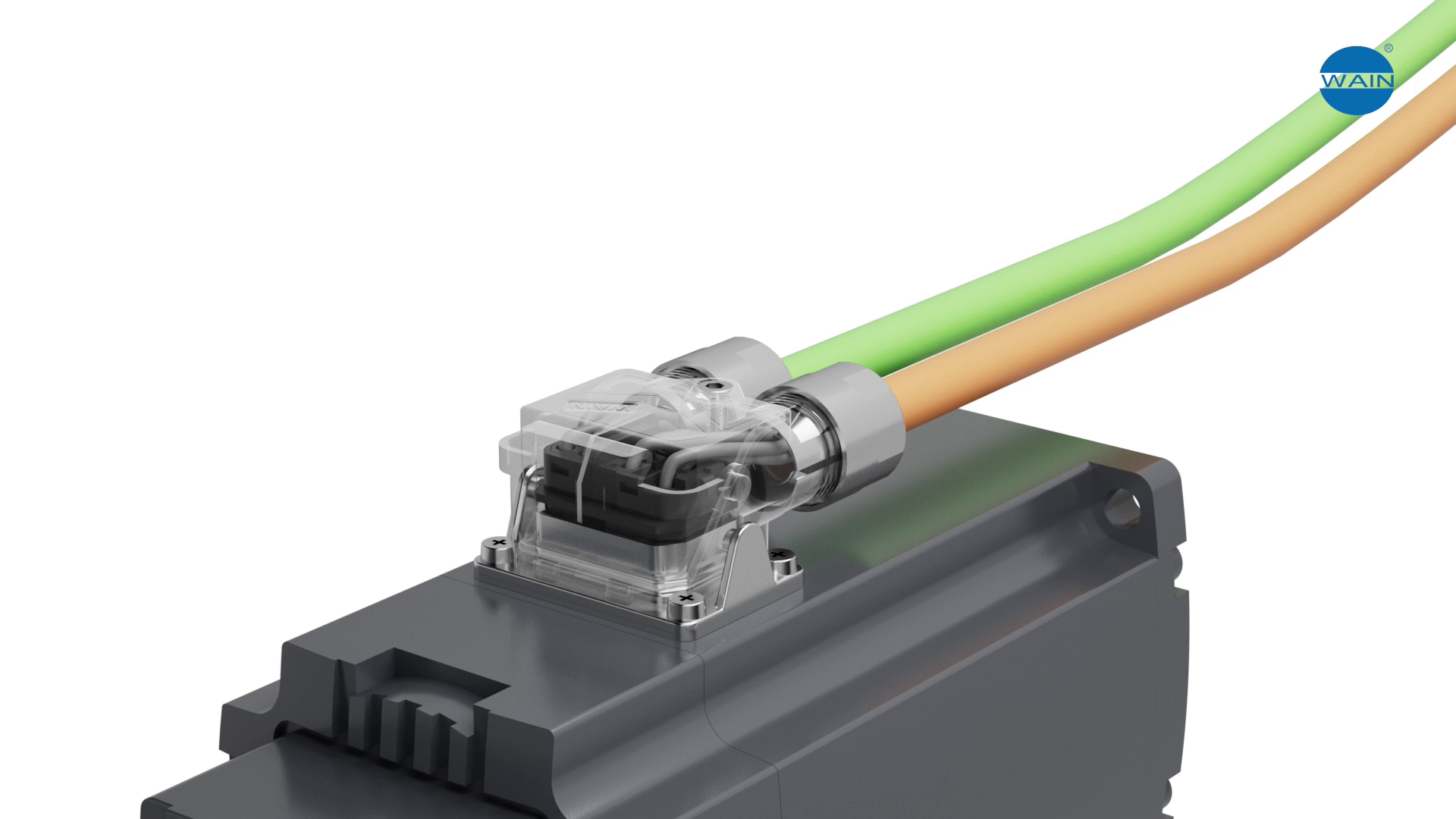

· MI connectors feature a compact form factor that is smaller than conventional products while integrating three functional modules—signal, power, and brake—into a single unit. This eliminates cable clutter and frees up valuable enclosure space, making the connectors easy to embed in robot joints, AGV control bays, or precision-instrument compartments.

· A partitioned, removable-module design allows users to detach either the signal or power section independently. If one module fails, the entire connector does not need to be replaced, dramatically reducing maintenance time and cost. Compared with traditional one-piece connectors, service efficiency is significantly improved.

Five Core Technology Innovations

1、One-Second Quick-Release — Latch Mechanism

MI connectors use an elastic latch-lock design that mates or unmated with a single press, cutting installation time. Anti-mis-mate coding ensures precise, reliable connections.

2、Vibration-Resistant Cold-Crimp Contacts

Contacts are cold-crimped—no soldering—delivering high-strength conductivity. Tested to withstand 500+ mating cycles, ideal for high-vibration environments such as industrial robots and rail systems.

3、360° Electromagnetic Shielding + Partitioned Isolation

Dual-layer protection:

• Outer full-metal shell blocks external EMI.

• Inner isolation chambers physically separate power and signal sections, eliminating crosstalk and guaranteeing zero-packet-loss data transmission.

4、Dual-Cable Exits for Flexible Routing

Independent power and signal channels exit through Ø 7.5 mm ports, accommodating large-gauge power and fine-gauge signal wires. The plug supports 180° dual-direction swivel, adapting to varied equipment layouts.

5、Visual Assembly — Top + Side Inspection Windows

Technicians can verify pin alignment in real time, preventing bent pins from blind mating. During service, windows enable rapid fault location, lowering technical complexity and downtime.

Proven in Harsh Environments

·Operating temperature: –40 °C … +130 °C

·Ingress protection: IP67 (mated, EN 60529) – suitable for aerospace and outdoor equipment